Foils

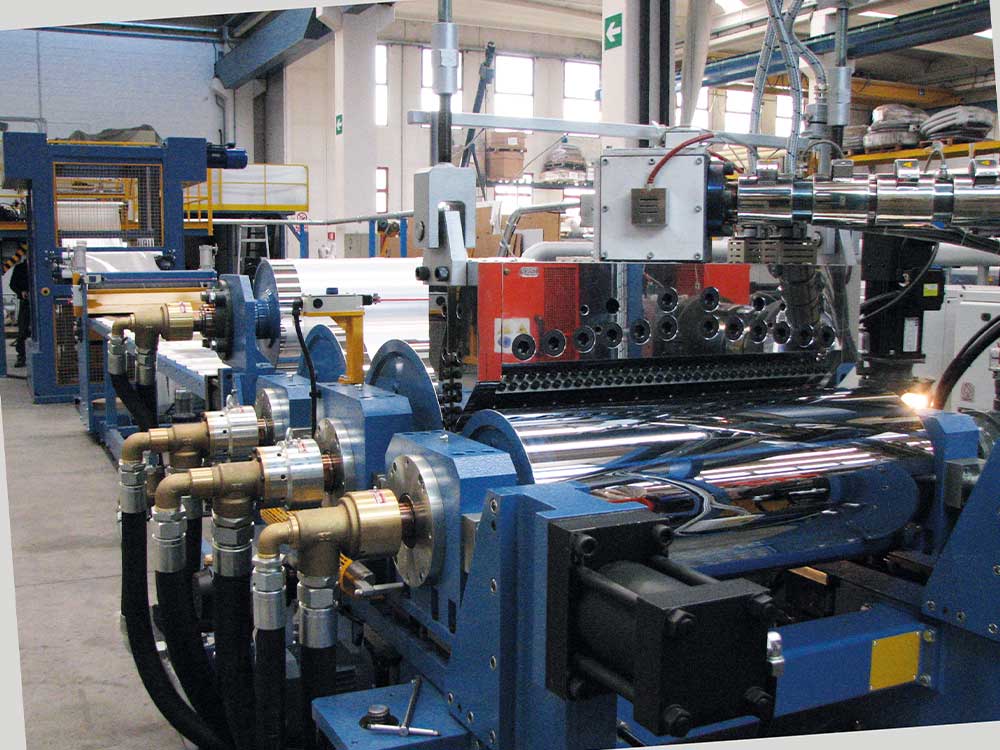

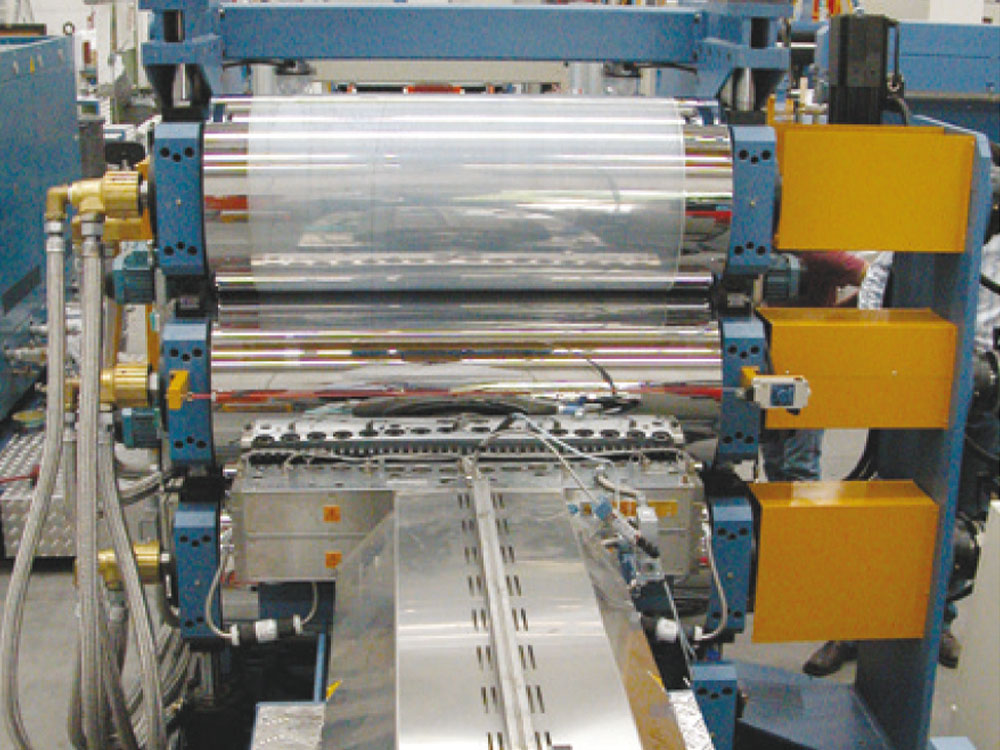

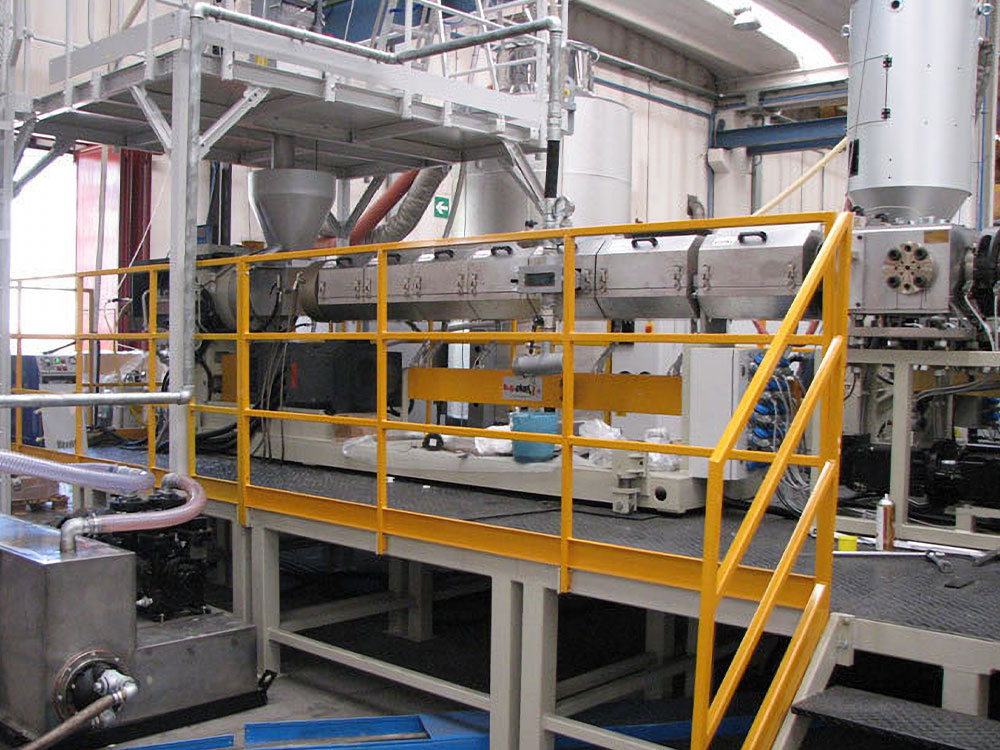

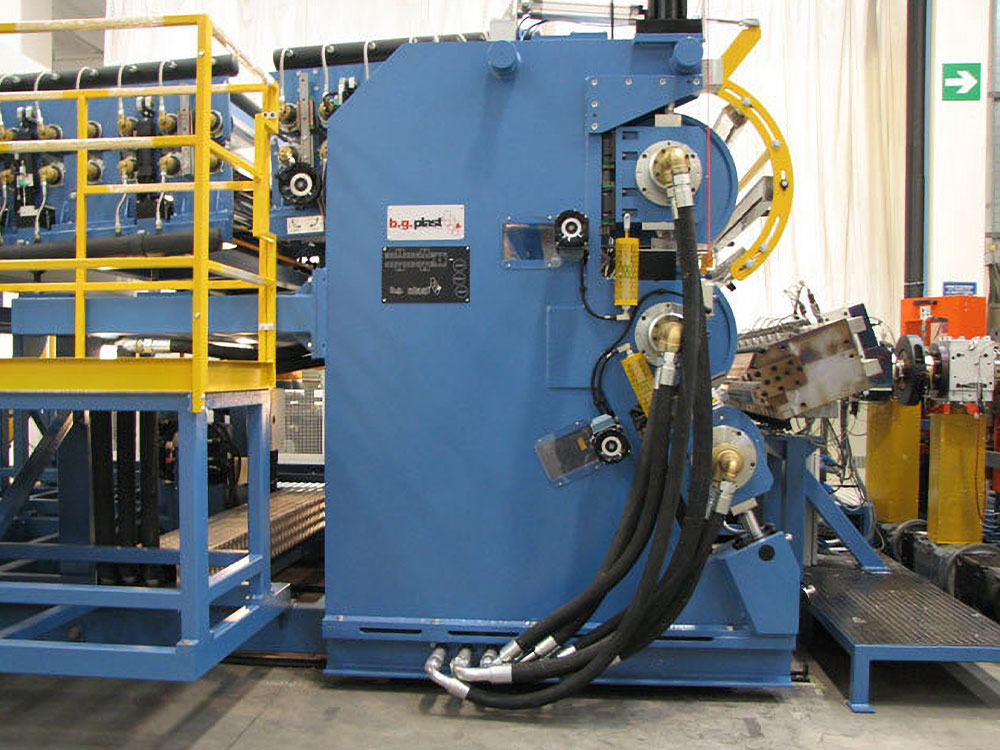

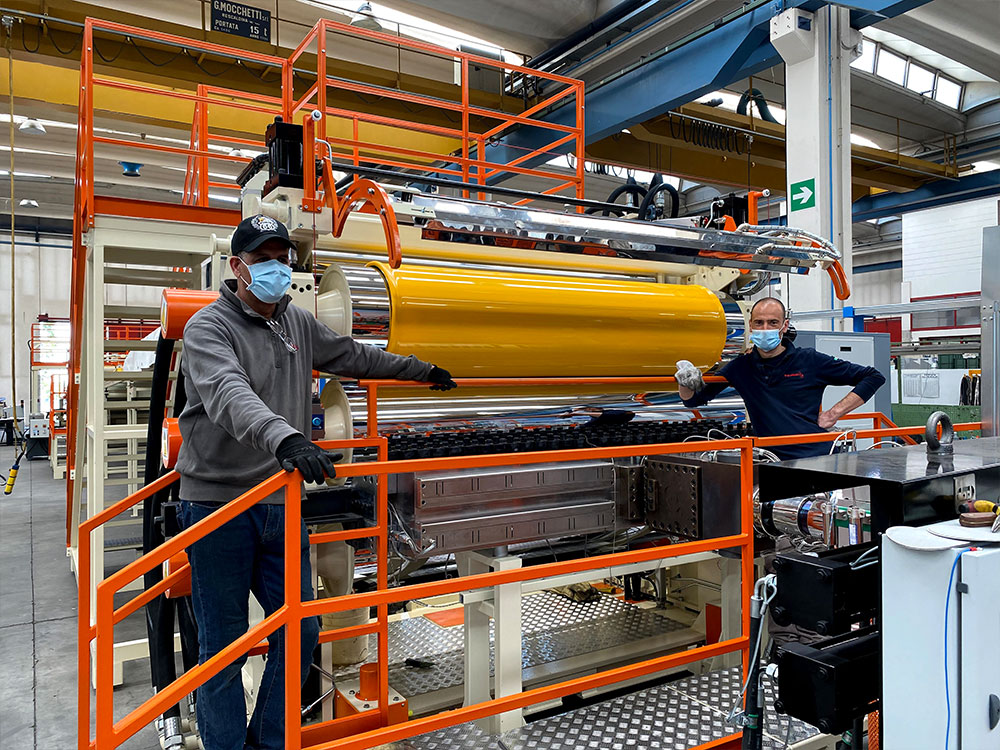

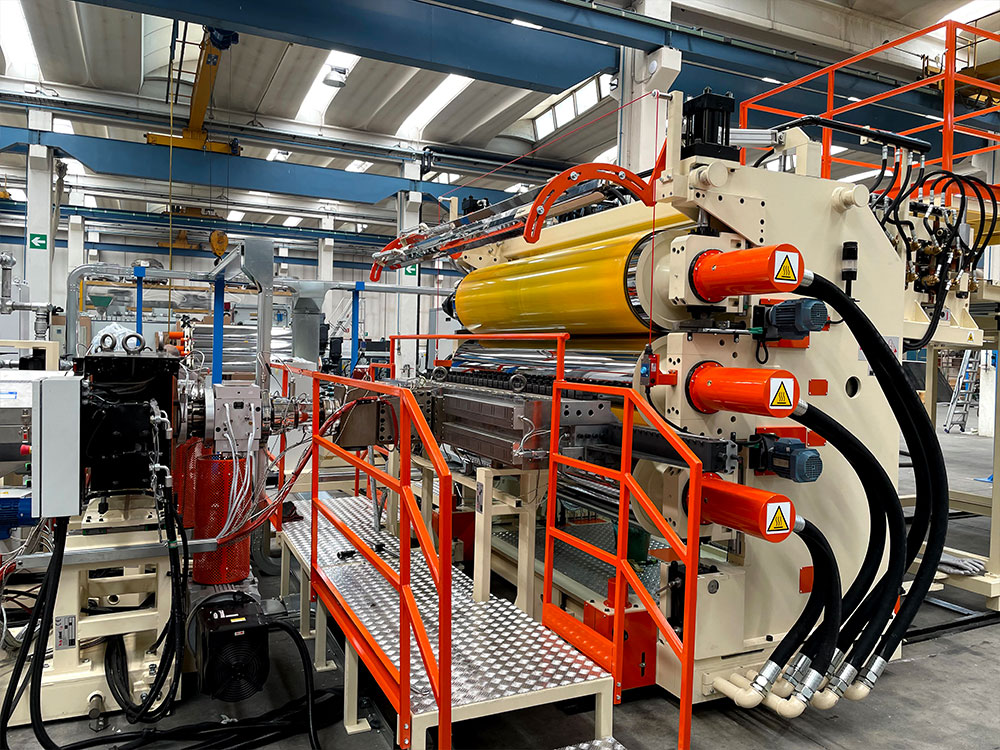

BG Plast is specialized in designing and manufacturing calenders with several geometries for the production of thermoplastic materials. These machines are the core of the extrusion process for the production of films and sheets.

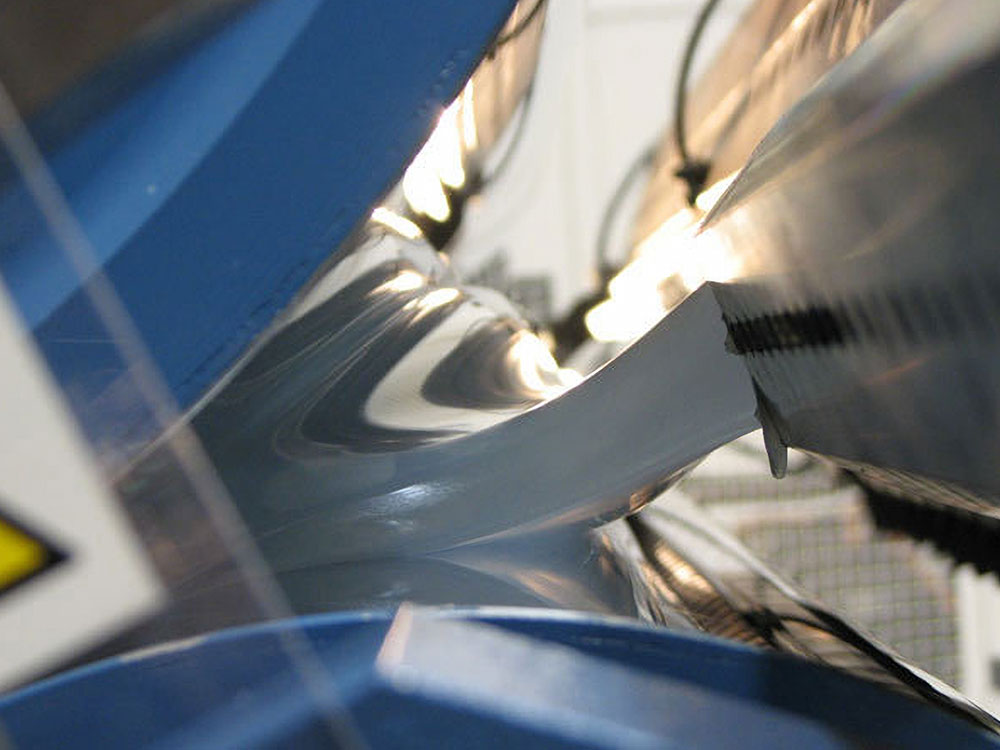

Thanks to a precision electromechanical control on roll opening and closing, we can guarantee thicknesses from 0.1 to 40 mm, depending on material.

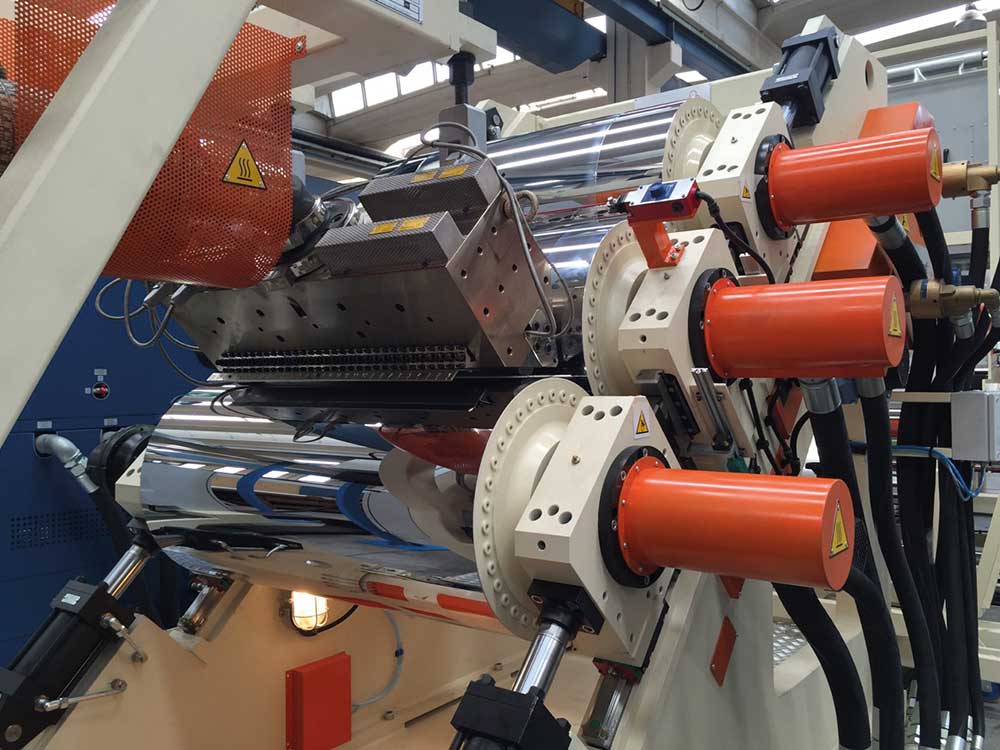

Closing force, expressed in “linear kg/cm”, is different according to type of polymer, being set by the size of the hydraulic pistons used for moving the rolls (from 80 to 120 linear kg/cm).

A separate thermoregulation unit controls water/oil flow and temperature for each roll. Each roll is driven by an independent gearbox.

In case of very thin sheets, there is a particular device called “cross-axis”, to shift the central roll shaft in relation to the other ones and improve the thickness regulation. This operation is useful to assure sheet thickness’ uniformity.

Sizes of BG Plast extrusion lines and calenders vary according to the final product, required by the customer. The width range of calender rolls goes from 450 mm to 8000 mm. Thanks also to the different types of feed-block configurations, BG Plast has faced several co-extrusion applications, using up to 7 extruders.

Applications