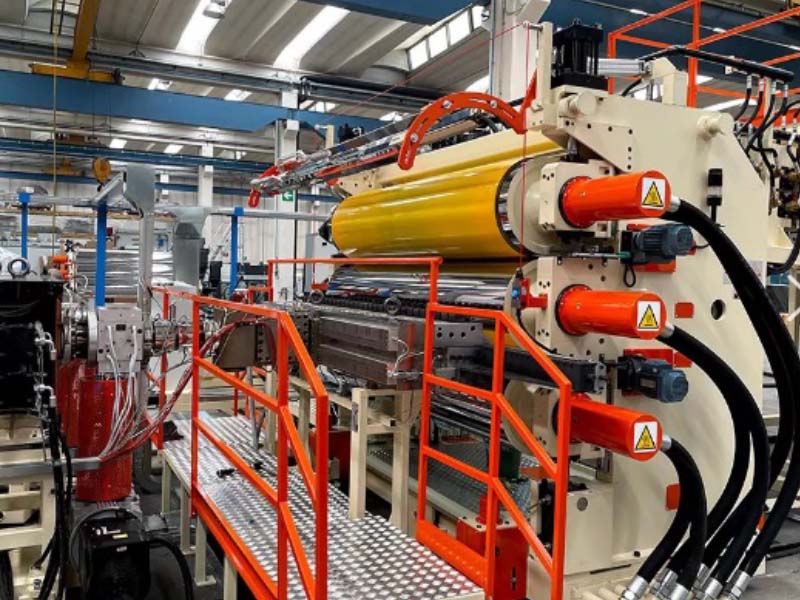

Among the most valued technologies in materials processing, multilayer polymeric foils extrusion is capable of revolutionizing packaging and industrial applications. In the engineering and manufacturing of high-performance extrusion and calendering machinery, BG Plast is a benchmark through experience and innovation.

What is multilayer extrusion?

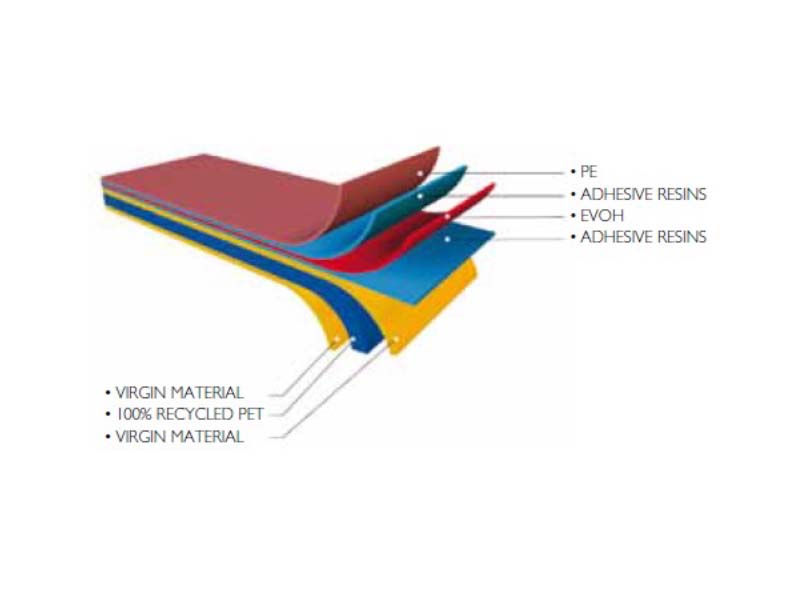

Multilayer extrusion is a process in which multiple polymers are combined to produce sheets and foils with a layered structure. The result is a material with improved physical and functional properties, such as barrier capacity, mechanical strength and aesthetics. Our extrusion and calendering machines excel in producing high-quality multilayer materials that meet diverse industrial needs.

BG Plast extrusion and calendering machinery enables the production of multilayer foils with thicknesses ranging from 0.15 to 1.8 mm

The role of multilayer extrusion in packaging

Food packaging: how to improve freshness and shelf life

Multilayer foils are indispensable in the food packaging industry. BG Plast’s advanced extrusion technology allows barrier layers such as EVOH (ethylene vinyl alcohol), which significantly reduce oxygen permeability, to be incorporated into production. This feature helps preserve food freshness, prevents contamination and extends shelf life-a key requirement in today’s supply chains.

Pharmaceutical applications for maximum precision and protection

In the pharmaceutical industry, ensuring the integrity of drugs and medical supplies is critical. Multilayer extrusion offers unparalleled protection against moisture, light and contaminants. Our systems make it possible to create highly durable and customizable multilayer foils that are ideal for blister packs and other pharmaceutical packaging needs.

Industrial applications of multilayer foils

Multilayer extrusion goes beyond packaging to a variety of industrial applications. BG Plast’s lines produce custom-made sheets and foils for:

– Construction. Acoustic and thermal insulation solutions.

– Automotive. Production of components with increased mechanical strength and light weight.

– Electronics. Creation of barrier materials for sensitive electronic components.

Materials that are extruded in this way are designed to meet industry-specific requirements, offering superior performance and cost efficiency.

Customization: tailor-made solutions with the highest precision

BG Plast is the ideal partner for industries looking for efficiency and accuracy because of our ability to customize extrusion equipment to the customer’s specific needs. From single-layer to seven-layer configurations, the possibilities are truly endless. The integration of materials such as PP, PE, PET and EVOH enables tailor-made solutions that meet the most demanding standards of various industries.

Among the possible configurations:

- Multilayer

- PP + PE

- PS + PE

- PS + Crystal

- With barrier

- PP + EVOH + PP

- PS + EVOH + PE

- PP + EVOH + PE

- PP + EVOH + PET

Infinite configurations for greater efficiency and versatility of extruded materials

The importance of EVOH layers

EVOH barrier layers represent a breakthrough in multilayer extrusion. They offer exceptional gas and chemical resistance while maintaining flexibility and versatility. BG Plast’s advanced feed block configurations ensure better distribution of EVOH layers, optimizing material use and performance.

BG Plast sustainability: less waste and reduced resource use

In addition to performance benefits, multilayer extrusion contributes to sustainability goals. By combining different functionalities into thinner layers, material use is minimized without compromising quality. Our extrusion and calendering machinery can also use recycled materials, such as 100% recycled PET, aligning with current circular economy principles.

Groundbreaking technology: the advantages of BG Plast

BG Plast’s extrusion equipment employs state-of-the-art technology to deliver unparalleled precision and efficiency. Key features include:

- Precision control. Electromechanical systems ensure consistent thickness of extruded and calendered foils, from 0.15 mm to 1.80 mm. Typical widths range from 550 to 1,600 mm. Other thicknesses and widths are available upon request.

- Customized geometries. Innovative cross-axis adjustments enable superior thickness uniformity.

- High productivity. Production capacity ranges from 250 to 2000 kg/h, to meet different industrial scales.

Why choose BG Plast for multilayer extrusion

With decades of experience, BG Plast combines technical expertise and commitment to innovation. From design to final testing, our extrusion and calendering lines are designed to deliver exceptional performance and reliability. For food packaging or a variety of industrial applications, choosing multilayer extrusion with BG Plast machinery means taking a step toward the future of sustainable efficiency.

Let’s transform the industry together: contact us for more information.